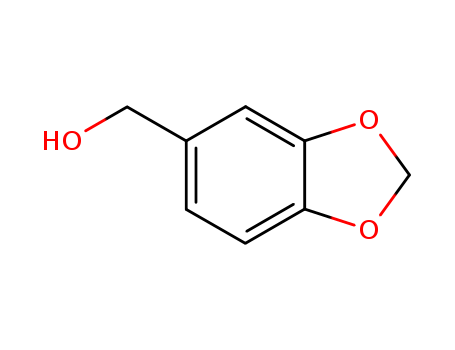

495-76-1

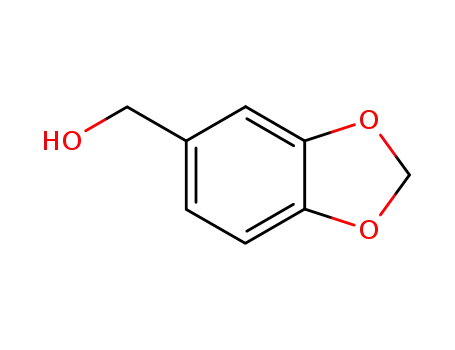

- Product Name:Piperonyl alcohol

- Molecular Formula:C8H8O3

- Purity:99%

- Molecular Weight:152.15

Product Details

pd_meltingpoint:50-54 °C(lit.)

Appearance:White crystals or crystalline powder

Factory Sells Best Quality Piperonyl alcohol 495-76-1 with ISO standards

- Molecular Formula:C8H8O3

- Molecular Weight:152.15

- Appearance/Colour:White crystals or crystalline powder

- Vapor Pressure:0.00161mmHg at 25°C

- Melting Point:50-54 °C(lit.)

- Refractive Index:1.594

- Boiling Point:282.2 °C at 760 mmHg

- PKA:14.36±0.10(Predicted)

- Flash Point:124.5 °C

- PSA:38.69000

- Density:1.329 g/cm3

- LogP:0.90760

Piperonyl alcohol(Cas 495-76-1) Usage

|

Synthesis Reference(s) |

Journal of the American Chemical Society, 71, p. 3657, 1949 DOI: 10.1021/ja01179a022 |

InChI:InChI=1/C8H8O3/c9-4-6-1-2-7-8(3-6)11-5-10-7/h1-3,9H,4-5H2

495-76-1 Relevant articles

A novel method to convert ketones and aldehydes to the corresponding alcohols

Wei-Dong, Yang,Chi, Yang,An-Xing, Wu

, p. 2827 - 2830 (1998)

A novel method of converting aldehydes a...

Degradation of the neolignan, burchellin in the hemolymph of the bloodsucking insect Rhodnius prolixus

Cabral, Marise M.O.,Garcia, Eloi S.,Gottlieb, Otto R.,Kelecom, Alphonse

, p. 59 - 63 (2008)

The neolignan, burchellin, a natural com...

Iron-catalyzed chemoselective hydride transfer reactions

Coufourier, Sébastien,Ndiaye, Daouda,Gaillard, Quentin Gaignard,Bettoni, Léo,Joly, Nicolas,Mbaye, Mbaye Diagne,Poater, Albert,Gaillard, Sylvain,Renaud, Jean-Luc

supporting information, (2021/06/07)

A Diaminocyclopentadienone iron tricarbo...

Efficient and chemoselective hydrogenation of aldehydes catalyzed by well-defined PN3-pincer manganese(ii) catalyst precursors: An application in furfural conversion

Gholap, Sandeep Suryabhan,Dakhil, Abdullah Al,Chakraborty, Priyanka,Li, Huaifeng,Dutta, Indranil,Das, Pradip K.,Huang, Kuo-Wei

supporting information, p. 11815 - 11818 (2021/11/30)

Well-defined and air-stable PN3-pincer m...

Light-driven MPV-type reduction of aryl ketones/aldehydes to alcohols with isopropanol under mild conditions

Cao, Dawei,Xia, Shumei,Pan, Pan,Zeng, Huiying,Li, Chao-Jun,Peng, Yong

supporting information, p. 7539 - 7543 (2021/10/12)

Alcohols are versatile structural motifs...

Method for synthesizing piperonyl alcohol through catalytic hydrogenation

-

Paragraph 0024-0035, (2021/02/10)

The invention relates to the technical f...

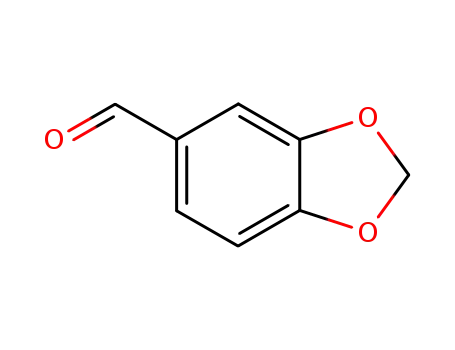

495-76-1 Process route

-

-

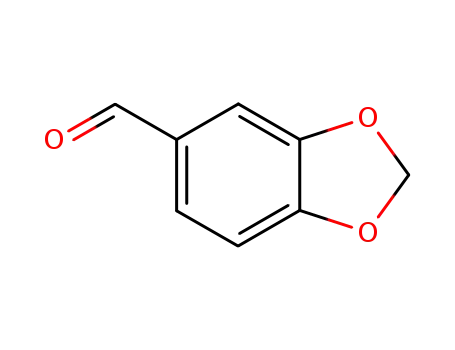

120-57-0,30024-74-9

piperonal

-

-

495-76-1

piperonol

| Conditions | Yield |

|---|---|

|

With

diisopropoxytitanium(III) tetrahydroborate;

In

dichloromethane;

at -20 ℃;

for 0.133333h;

|

100% |

|

With

Zn(BH4)2(Ph3P)2;

In

tetrahydrofuran;

at 20 ℃;

|

100% |

|

With

sodium tetrahydroborate;

In

methanol;

at 20 ℃;

for 1h;

|

100% |

|

With

hydrogen;

In

water;

at 40 ℃;

for 0.00611111h;

under 22502.3 Torr;

chemoselective reaction;

Flow reactor;

Green chemistry;

|

99% |

|

With

trimethylamine-N-oxide; (1,4-dimethyl-5,7-diphenyl-1,2,3,4-tetrahydro-6H-cyclopenta[b]pyrazin-6-one) irontricarbonyl complex3; potassium formate;

In

ethanol;

at 45 - 60 ℃;

for 24h;

Inert atmosphere;

Schlenk technique;

|

99% |

|

antimony(III) chloride; aluminium;

In

water; N,N-dimethyl-formamide;

for 1h;

Ambient temperature;

|

98% |

|

With

water; antimony(III) chloride; aluminium;

In

N,N-dimethyl-formamide;

for 1h;

Ambient temperature;

|

98% |

|

With

water; nickel dichloride; zinc;

In

N,N-dimethyl-formamide;

for 1h;

Ambient temperature;

|

98% |

|

With

cobalt(II) chloride; zinc;

In

water; N,N-dimethyl-formamide;

for 1.5h;

Ambient temperature;

|

98% |

|

With

bis(triphenylphosphine)copper(I) nitrate; hydrogen; 1,4-di(diphenylphosphino)-butane; sodium hydroxide;

In

ethanol;

at 50 ℃;

for 16h;

under 37503.8 Torr;

chemoselective reaction;

Autoclave;

Inert atmosphere;

|

98% |

|

With

sodium tetrahydroborate;

In

methanol;

at 0 ℃;

for 0.25h;

Inert atmosphere;

|

98% |

|

With

hydrogen; sodium hydroxide;

bis(triphenylphosphane)copper(I) nitrate; 1,4-di(diphenylphosphino)-butane;

In

ethanol;

at 50 ℃;

for 16h;

under 37503.8 Torr;

Autoclave;

Inert atmosphere;

|

98% |

|

With

hydrogen; sodium hydroxide;

bis(triphenylphosphane)copper(I) nitrate; 1,4-di(diphenylphosphino)-butane;

In

ethanol;

at 50 ℃;

for 16h;

under 37503.8 Torr;

Autoclave;

Inert atmosphere;

|

98% |

|

With

methanol; sodium tetrahydroborate;

at 0 - 20 ℃;

for 0.5h;

|

98% |

|

With

sodium tetrahydroborate; sodium hydroxide;

In

methanol; water;

at 20 ℃;

for 0.833333h;

|

97% |

|

With

hydrogen;

In

methanol;

at 20 ℃;

for 4h;

chemoselective reaction;

|

97% |

|

With

(1,4-diazabicyclo{2.2.2}-octane)zinc(II) tetrahydoborate;

In

tetrahydrofuran;

for 6.5h;

Ambient temperature;

|

96% |

|

With

cyclopentylmagnesium bromide;

In

tetrahydrofuran;

at 20 ℃;

for 3h;

|

95% |

|

With

trimethylamine-N-oxide; sodium formate; C34H44FeN4O4(2+)*2I(1-);

In

water;

at 80 ℃;

for 24h;

Inert atmosphere;

Schlenk technique;

|

95% |

|

With

diethyl 2,6-dimethyl-1,4-dihydropyridine-3,5-dicarboxylate; tris[3,5-bis(trifluoromethyl)phenyl]-borane;

In

1,4-dioxane;

at 25 ℃;

for 12h;

Glovebox;

|

94% |

|

With

ethanol; aluminium; sodium iodide;

for 6h;

Electrolysis;

refluxe;

|

93% |

|

With

sodium tetrahydroborate;

In

ethanol;

at 40 ℃;

for 3h;

|

92.8% |

|

With

sodium tetrahydroborate; ethanol;

at 40 ℃;

for 3h;

|

92.8% |

|

With

methyltriphenylphosphonium tetrahydroborate;

In

dichloromethane;

|

91% |

|

With

Decaborane;

In

tetrahydrofuran; water;

at 20 ℃;

for 0.5h;

|

91% |

|

piperonal;

With

polymethylhydrosiloxane; iron(II) acetate; tricyclohexylphosphine;

In

tetrahydrofuran;

at 65 ℃;

for 16h;

With

sodium hydrogencarbonate;

In

tetrahydrofuran; methanol;

at 0 - 20 ℃;

Further stages.;

|

91% |

|

With

sulfurated borohydride exchange resin;

In

methanol;

at 25 ℃;

for 0.166667h;

|

90% |

|

With

triethylsilane; water; palladium diacetate;

In

N,N-dimethyl-formamide;

at 25 ℃;

for 1h;

|

90% |

|

With

sodium tetrahydroborate;

In

methanol;

at 0 - 25 ℃;

for 4h;

|

90% |

|

With

platinum on activated charcoal; hydrogen;

In

ethanol;

at 20 ℃;

for 3h;

|

89% |

|

With

potassium fluoride on basic alumina; formaldehyd;

for 0.116667h;

microwave irradiation;

|

88% |

|

With

sodium tetrahydroborate; nickel dichloride;

In

tetrahydrofuran;

at 20 ℃;

for 0.0833333h;

|

86% |

|

With

magnesium; tin(ll) chloride;

In

tetrahydrofuran;

for 0.25h;

|

85% |

|

With

potassium tert-butylate; hydrogen; C18H26Br2MnN3P;

In

methanol;

under 20252 Torr;

chemoselective reaction;

Inert atmosphere;

Autoclave;

|

85% |

|

With

hexarhodium hexadecacarbonyl; carbon monoxide; aminated polymer; water;

In

benzene;

at 80 ℃;

for 24h;

under 11400 Torr;

|

83% |

|

With

indium isopropoxide; isopropyl alcohol;

for 2h;

Inert atmosphere;

|

83% |

|

With

hydrogen;

copper chromite;

In

1,4-dioxane;

at 170 - 175 ℃;

for 2h;

under 136800 - 174800 Torr;

Product distribution;

other temp., pressure; other substrates, reagents;

|

80% |

|

With

hydrogen;

copper chromite;

In

1,4-dioxane;

at 170 - 175 ℃;

for 2h;

under 136800 - 174800 Torr;

|

80% |

|

piperonal;

With

1-Methylpyrrolidine; 2-chloro-5-fluorophenylboronic acid; phenylsilane;

at 20 ℃;

for 16h;

Inert atmosphere;

With

sodium hydroxide;

In

water;

at 20 ℃;

for 2h;

chemoselective reaction;

|

74% |

|

With

lithium tert-butoxide;

In

isopropyl alcohol;

at 20 ℃;

for 36h;

UV-irradiation;

Inert atmosphere;

|

73% |

|

With

phenylselenomagnesium bromide;

In

tetrahydrofuran;

for 13h;

Ambient temperature;

|

56.1% |

|

With

hydrazine hydrate;

In

tetrahydrofuran;

at 20 ℃;

for 24h;

Sealed tube;

|

49% |

|

With

triethylsilane; zinc(II) iodide;

In

1,2-dichloro-ethane;

at 20 ℃;

for 6h;

|

30% |

|

With

lithium aluminium tetrahydride; diethyl ether;

|

|

|

With

acetic acid ester; hydrogen;

weitere Reagens Platinschwarz;

|

|

|

With

ethanol; hydrogen;

weitere Reagens Platinschwarz;

|

|

|

With

platinum(IV) oxide; ethanol; iron(II) chloride;

under 2280 Torr;

Hydrogenation;

|

|

|

With

Pd-BaSO4; acetic acid;

Hydrogenation;

|

|

|

With

sodium hydrogencarbonate; mercury;

at 10 - 12 ℃;

Electrolysis;

|

|

|

With

methanol;

|

|

|

With

ethanol;

|

|

|

With

methanol; palladium; N,N-diethylnicotinamide;

at 20 ℃;

Hydrogenation;

|

|

|

With

palladium on activated charcoal; isopropyl alcohol;

at 70 - 90 ℃;

under 29420.3 Torr;

|

|

|

With

1,4-dioxane; copper oxide-chromium oxide;

at 160 - 175 ℃;

under 220652 Torr;

Hydrogenation;

|

|

|

With

ethanol; nickel;

at 35 - 60 ℃;

Hydrogenation.unter Druck;

|

|

|

With

potassium hydroxide; benzyl alcohol;

at 205 ℃;

|

|

|

With

aluminum isopropoxide; isopropyl alcohol;

|

|

|

With

potassium hydroxide;

at 20 ℃;

|

|

|

With

nickel; decalin;

at 120 - 130 ℃;

Hydrogenation;

|

|

|

With

sodium tetrahydroborate;

In

ethanol;

|

|

|

With

sodium tetrahydroborate;

In

methanol; dichloromethane;

for 1h;

|

|

|

With

methanol; methyltriphenylphosphonium tetrahydroborate;

Yield given. Multistep reaction;

1) CH2Cl2, room temperature, 1 min, 2) 1 h;

|

|

|

With

sodium hydroxide; polymethylhydrosiloxane; tetrabutyl ammonium fluoride;

Yield given. Multistep reaction;

1.) THF, room t., 2.) THF;

|

|

|

With

sodium hydroxide; sodium tetrahydroborate; zinc 2-ethylhexanoate;

Yield given;

Multistep reaction;

1.) THF, reflux, 2.) 40 deg, 1 h;

|

|

|

With

sodium tetrahydroborate; silica gel;

In

hexane;

at 40 ℃;

for 3h;

Yield given;

|

|

|

With

sodium tetrahydroborate;

In

methanol;

at 20 ℃;

|

|

|

With

sodium tetrahydroborate;

In

ethanol;

at 0 - 20 ℃;

|

|

|

With

sodium tetrahydroborate;

In

tetrahydrofuran; water;

at 20 ℃;

|

|

|

With

sodium tetrahydroborate;

In

methanol;

|

|

|

With

sodium tetrahydroborate;

|

|

|

With

potassium tert-butylate; hydrogen;

(N,N'-bis(2-(tert-butylthio-κS)benzylidene)-1,2-ethanediamino-κN,κN')dichlororuthenium(II);

In

isopropyl alcohol;

at 60 ℃;

for 2h;

under 37503.8 Torr;

Product distribution / selectivity;

autoclave;

|

99 %Chromat. |

|

With

sodium tetrahydroborate;

In

dichloromethane;

at 20 ℃;

for 0.5h;

|

|

|

With

(N,N'-bis(2-(tert-butylthio-kS)benzylidene)-1,2-ethanediamino-kN,kN')dichlororuthenium(II); potassium tert-butylate; hydrogen;

In

isopropyl alcohol;

at 60 ℃;

for 2h;

under 37503.8 Torr;

Inert atmosphere;

Autoclave;

|

99 %Chromat. |

|

With

sodium tetrahydroborate;

In

methanol;

at 0 - 20 ℃;

for 0.5h;

|

|

|

With

sodium tetrahydroborate;

In

methanol;

at -10 ℃;

|

188.8 mg |

|

With

sodium tetrahydroborate;

In

methanol;

Sealed tube;

|

|

|

With

methanol; sodium tetrahydroborate;

at 20 ℃;

Schlenk technique;

Inert atmosphere;

|

|

|

With

sodium tetrahydroborate;

In

ethanol;

at 25 ℃;

for 0.5h;

|

|

|

With

sodium tetrahydroborate;

In

methanol;

|

|

|

With

[(iPr-PNP)Fe(H)(Br)(CO)]; potassium tert-butylate; hydrogen; triethylamine;

In

ethanol;

at 40 ℃;

for 16h;

under 22502.3 Torr;

Autoclave;

|

94 %Spectr. |

|

With

potassium borohydride;

In

methanol; water;

at 20 ℃;

for 2h;

|

|

|

With

sodium tetrahydroborate;

In

methanol;

for 2h;

|

|

|

With

sodium tetrahydroborate;

In

methanol;

at 20 ℃;

Inert atmosphere;

Schlenk technique;

|

|

|

Multi-step reaction with 2 steps

1: C23H33MnN3Si2 / diethyl ether / 16 h / 25 °C / Glovebox; Inert atmosphere

2: silica gel / ethyl acetate; hexane

With

C23H33MnN3Si2; silica gel;

In

diethyl ether; hexane; ethyl acetate;

|

|

|

Multi-step reaction with 2 steps

1.1: pyridine / dichloromethane / 0.08 h / 25 °C

1.2: 12 h / 25 °C

2.1: sodium tetrahydroborate / tetrahydrofuran; water / 12 h / 0 - 25 °C

With

pyridine; sodium tetrahydroborate;

In

tetrahydrofuran; dichloromethane; water;

|

|

|

Multi-step reaction with 2 steps

1: sodium metabisulfite / water / 12 h / 20 °C / Cooling with ice

2: sodium tetrahydroborate; ethanol / 0.75 h / 20 °C

With

sodium metabisulfite; sodium tetrahydroborate; ethanol;

In

water;

|

|

|

Multi-step reaction with 2 steps

1: sodium hydroxide / di-isopropyl ether / 6 h / 20 °C

2: sodium tetrahydroborate; ethanol / 0.75 h / 20 °C

With

sodium tetrahydroborate; ethanol; sodium hydroxide;

In

di-isopropyl ether;

|

|

|

Multi-step reaction with 2 steps

1: cis-[(H)(SePh)Fe(PMe3)4] / tetrahydrofuran / 2 h / 50 °C

2: sodium hydroxide; methanol / 50 °C

With

methanol; cis-[(H)(SePh)Fe(PMe3)4]; sodium hydroxide;

In

tetrahydrofuran;

|

|

|

With

zirconium(IV) pyrophosphate;

In

isopropyl alcohol;

at 160 ℃;

for 10h;

|

|

|

Multi-step reaction with 2 steps

1: [CoCl2(4'-(4-pyridyl)-2,2':6',2''-terpyridine)]·2H2O; potassium tert-butylate / tetrahydrofuran / 16 h / 25 °C / Inert atmosphere; Glovebox

2: silica gel / 25 °C / Inert atmosphere; Glovebox

With

[CoCl2(4'-(4-pyridyl)-2,2':6',2''-terpyridine)]·2H2O; potassium tert-butylate; silica gel;

In

tetrahydrofuran;

|

|

|

With

water; nickel;

at 50 - 70 ℃;

under 73550.8 Torr;

Hydrogenation;

|

|

|

Multi-step reaction with 2 steps

1: two-dimensional iron(II) coordination polymer based on a divergent 4'-(4-diphenylamino)phenyl-4,2';6',4''-terpyridine ligand; potassium tert-butylate / neat (no solvent) / 0.5 h / 20 °C / Green chemistry

2: silica gel / ethyl acetate; hexane / 20 °C

With

two-dimensional iron(II) coordination polymer based on a divergent 4'-(4-diphenylamino)phenyl-4,2';6',4''-terpyridine ligand; potassium tert-butylate; silica gel;

In

hexane; ethyl acetate;

|

|

|

With

sodium tetrahydroborate;

In

methanol;

at 20 ℃;

for 18h;

|

|

|

Multi-step reaction with 2 steps

1: 0.55C27H43N3Si3V*0.45C27H44N3Si3V / diethyl ether / 2 h / 20 °C / Inert atmosphere; Glovebox; Schlenk technique

2: air / diethyl ether

With

0.55C27H43N3Si3V*0.45C27H44N3Si3V;

In

diethyl ether;

|

|

|

With

hydrogen;

In

ethanol;

at 70 - 80 ℃;

for 4h;

under 375.038 - 15001.5 Torr;

Temperature;

Solvent;

Pressure;

|

100.1 g |

|

With

methanol; sodium tetrahydroborate;

at 0 - 20 ℃;

Inert atmosphere;

|

-

![5-(tetrahydro-2H-pyran-2-yloxy)methylbenzo[d][1,3]dioxole](/upload/2024/12/ae51f423-f34d-448e-889e-885e3b4b4ac4.png)

-

85604-71-3

5-(tetrahydro-2H-pyran-2-yloxy)methylbenzo[d][1,3]dioxole

-

-

495-76-1

piperonol

| Conditions | Yield |

|---|---|

|

With

trichloroisocyanuric acid;

In

methanol;

at 20 ℃;

for 4h;

|

92% |

|

With

cerium(III) chloride;

In

methanol;

at 20 ℃;

for 0.5h;

|

90% |

|

With

carbon tetrabromide;

In

methanol;

at 65 ℃;

for 0.5h;

Heating;

|

89% |

|

With

water; lithium chloride;

In

dimethyl sulfoxide;

at 90 ℃;

for 6h;

|

88% |

|

With

copper dichloride;

In

methanol;

at 20 ℃;

|

87% |

|

With

CuCl2*2H2O;

In

methanol;

at 20 ℃;

for 1.25h;

|

87% |

|

With

tin(ll) chloride;

In

methanol;

|

86% |

|

With

water;

β‐cyclodextrin;

In

methanol;

at 50 ℃;

for 10h;

|

80% |

495-76-1 Upstream products

-

120-57-0

piperonal

-

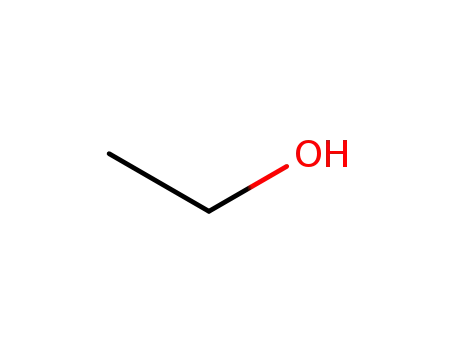

64-17-5

ethanol

-

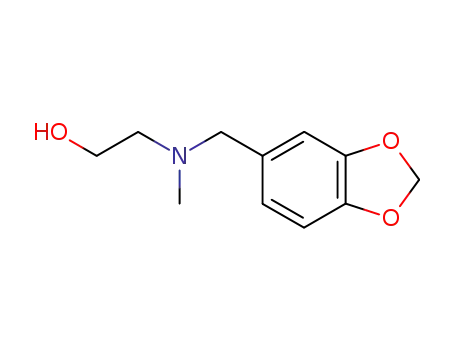

91247-76-6

2-(methyl-piperonyl-amino)-ethanol

-

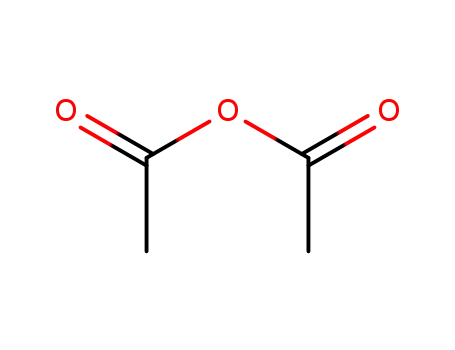

108-24-7

acetic anhydride

495-76-1 Downstream products

-

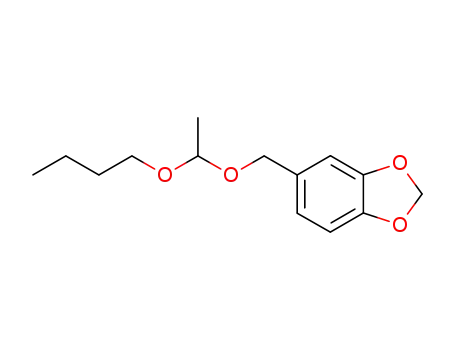

5442-27-3

5-(1-butoxy-ethoxymethyl)-benzo[1,3]dioxole

-

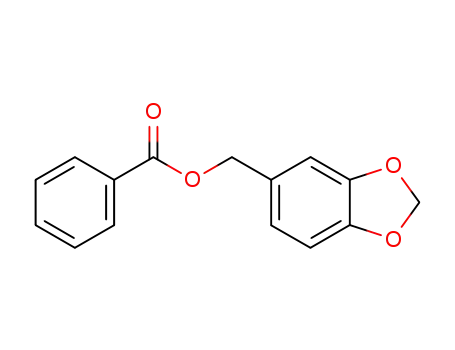

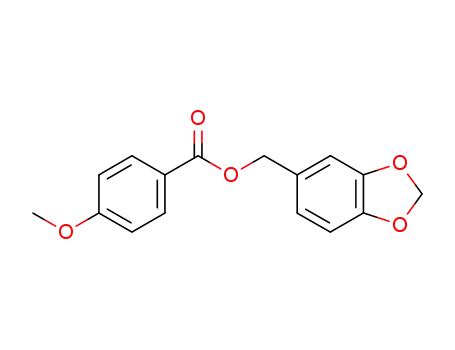

5469-06-7

benzo[d][1,3]dioxol-5-ylmethyl benzoate

-

5432-93-9

4-methoxy-benzoic acid piperonyl ester

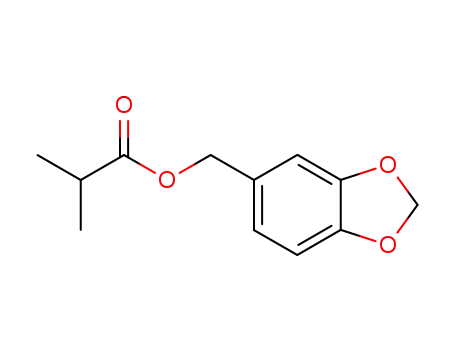

-

5461-08-5

3,4-methylenedioxybenzyl isobutanoate

Relevant Products

-

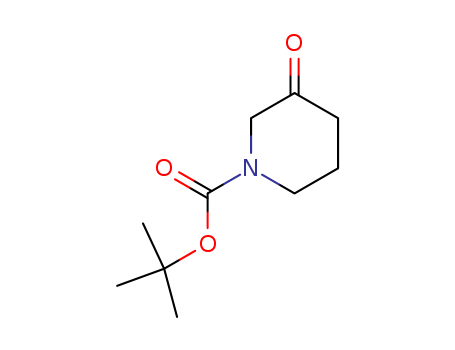

1-Boc-3-Piperidinone

CAS:98977-36-7

-

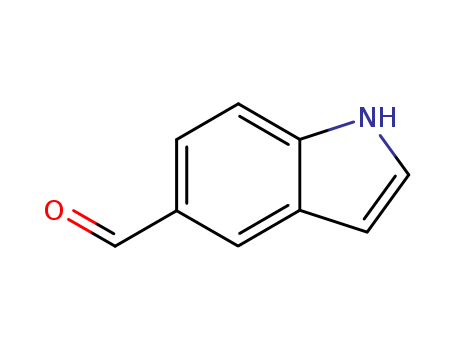

Indole-5-carboxaldehyde

CAS:1196-69-6

-

Piperonyl butoxide

CAS:51-03-6